Green Chem., 2016, Advance Article

DOI: 10.1039/C6GC00932H, Paper

DOI: 10.1039/C6GC00932H, Paper

James Sherwood, Helen L. Parker, Kristof Moonen, Thomas J. Farmer, Andrew J. Hunt

N-Butylpyrrolidinone (NBP) has been demonstrated as a suitable safer replacement solvent for N-Methylpyrrolidinone (NMP) in selected organic syntheses.

N-Butylpyrrolidinone (NBP) has been demonstrated as a suitable safer replacement solvent for N-Methylpyrrolidinone (NMP) in selected organic syntheses.

N-Butylpyrrolidinone as a dipolar aprotic solvent for organic synthesis

*Corresponding authors

aGreen Chemistry Centre of Excellence, Department of Chemistry, University of York, UK

E-mail: andrew.hunt@york.ac.uk

E-mail: andrew.hunt@york.ac.uk

bEastman Chemical Company, Pantserschipstraat 207 – B-9000, Gent, Belgium

Green Chem., 2016, Advance Article

DOI: 10.1039/C6GC00932H

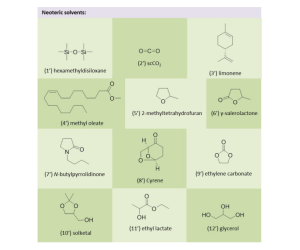

Dipolar aprotic solvents such as N-methylpyrrolidinone

(or 1-methyl-2-pyrrolidone (NMP)) are under increasing pressure from

environmental regulation. NMP is a known reproductive toxin and has been

placed on the EU “Substances of Very High Concern” list. Accordingly

there is an urgent need for non-toxic alternatives to the dipolar

aprotic solvents. N-Butylpyrrolidinone, although structurally

similar to NMP, is not mutagenic or reprotoxic, yet retains many of the

characteristics of a dipolar aprotic solvent. This work introduces N-butylpyrrolidinone

as a new solvent for cross-coupling reactions and other syntheses

typically requiring a conventional dipolar aprotic solvent.

////N-Butylpyrrolidinone, dipolar aprotic solvent , organic synthesis

The enzyme cyclic GMP-AMP synthase stimulates the immune response during HIV infections

The enzyme cyclic GMP-AMP synthase stimulates the immune response during HIV infections